Terra Grip Mug is one of these wonderful pieces, demonstrating the ageless elegance and practicality of terracotta craftsmanship. In this blog, we will explore the distinct charm of Terra Grip Mugs, delve into the labor-intensive manufacturing process, and highlight the crucial roles played by the artists who create these mugs.

The Beauty of Terra Grip Mugs

Terra Grip Mugs are works of art that convey a tale of custom, culture, and unmatched craftsmanship. Indeed, they are more than just drinking glasses. Their remarkable grip, derived from their distinctive shape, makes them not only aesthetically beautiful but also useful for daily use. Furthermore, the artisans frequently glaze the interior of the Terra Grip Mug to make it safe for handling liquids while still preserving the earthy appeal of terracotta with its unglazed surface.

The Procedure for Make Terra Grip Mugs

The artisans’ talent and attention to detail are crucial at every step of the laborious process involved in making Terra Grip Mugs.This is a closer look at the process that goes from clay to the final product.

- Clay Preparation – The artisans source high-quality clay, which forms the foundation of any terracotta product. They carefully select, clean, and knead the clay to achieve the right consistency. This step is crucial as it ensures the clay is free from impurities that could affect the final product’s durability and appearance.

- Shaping the Mug – This is where the artisan’s expertise truly shines. The potter uses their hands and simple tools to mold the clay, giving the mug its distinctive shape and grip. Each mug is unique, bearing the personal touch of the artisan.

- Drying – After shaping, the mugs are left to dry naturally. This drying period can take several days and is critical to prevent cracks during firing. The mugs must dry slowly and evenly, which requires a controlled environment.

- Firing – Once the artisans thoroughly dry the mugs, they fire them in a kiln at high temperatures. This process hardens the clay, making it durable and ready for everyday use. The kiln operator carefully monitors the firing process for several hours to ensure even heating and prevent damage.

- Glazing – After the first firing, the interior of the mugs is often glazed. This not only enhances the mug’s appearance but also ensures it is safe for holding hot and cold beverages. The glazing process involves dipping the mug into a glaze mixture and then firing it again to set the glaze.

- Final Inspection – The final step involves a thorough inspection of each mug. Subsequently, artisans check for any defects or imperfections, thereby ensuring that only the highest quality products make it to the market. Consequently, this step guarantees that every Terra Grip Mug is a testament to Tanutra’s commitment to quality and craftsmanship.

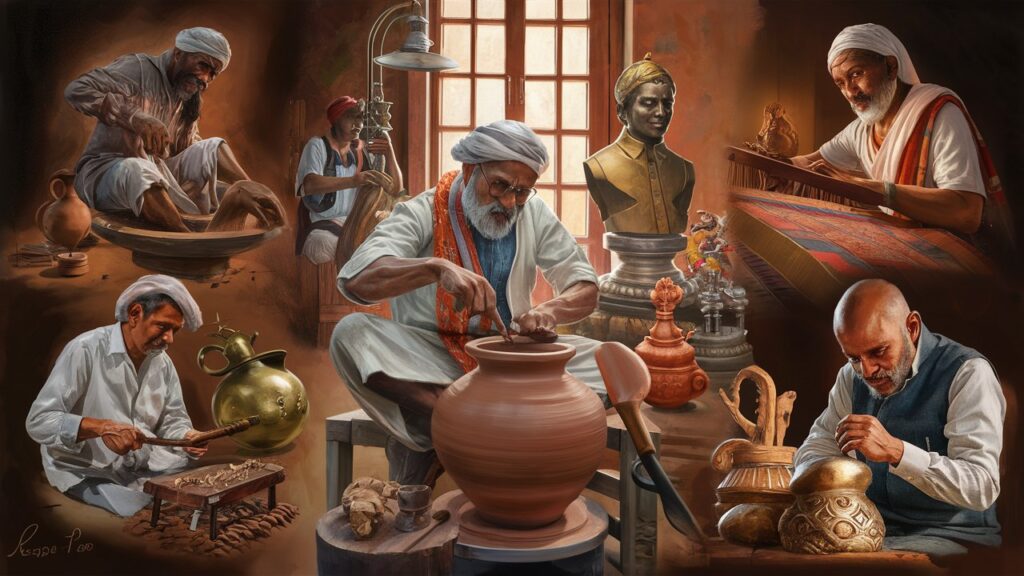

The Essential Roles of Artisans

Every Terra Grip Mug is the result of a group of talented artisans who lend their knowledge and enthusiasm to the creation process. Some of the key responsibilities in this are as follows:

- Clay Sourcing Specialists – These individuals oversee finding and preparing the clay. Consequently, the quality of the finished product greatly depends on their familiarity with the local clay deposits and their capacity to properly prepare the clay.

- Potters – The center of the production process is the potters. Indeed, the Terra Grip Mug’s distinctive shape and usefulness result from their exceptional skill in molding the clay on the wheel. Furthermore, every potter adds their unique touch to the creation process, making each mug a one-of-a-kind item.

- Kiln Operators – Kiln operators must fire the cups. They achieve the right level of hardness and durability in the firing of the mugs thanks to their skill in controlling the temperature and timing of the kiln.

- Glazers – Glazers coat the mugs in glaze, improving both their look and use. To achieve the ideal finish, their glaze application accuracy and comprehension of the fire procedure are crucial.

- Quality Inspectors – Tanutra has very high requirements for the finished product; therefore, quality inspectors are essential to achieving this. They meticulously check every mug for flaws and, as a result, ensure that only the best items are sent to clients. Consequently, Tanutra maintains its reputation for excellence and customer satisfaction.

Conclusion

Ready to experience the charm of Terra Grip Mugs for yourself? If so, visit Tanutra’s e-commerce platform to explore our collection of authentic, handcrafted Indian products. Moreover, elevate your daily rituals with the timeless elegance of terracotta and seamlessly bring a piece of India’s rich cultural heritage into your home.